The $45 Billion Automation Mistake

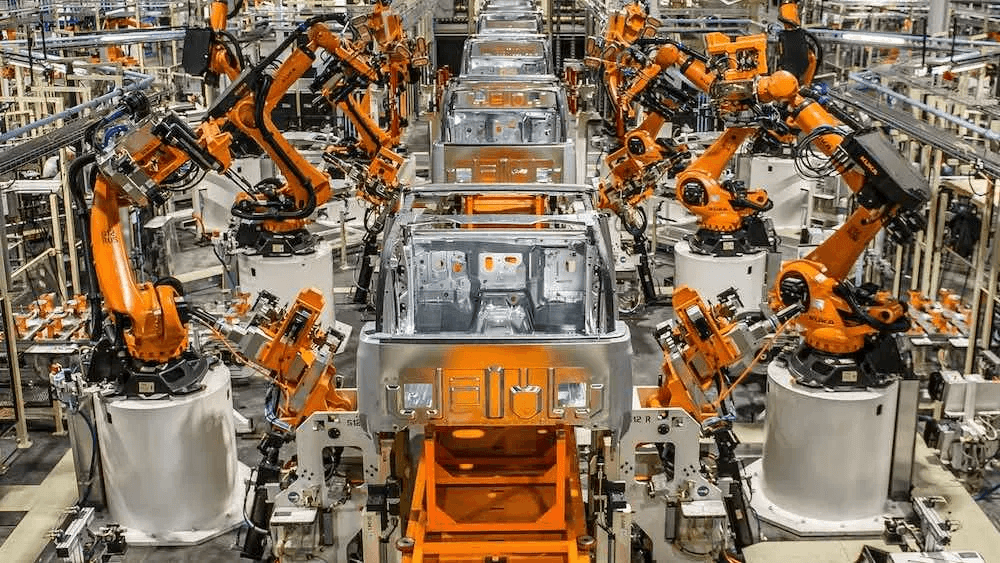

This is a lesson from GM's billion-dollar automation failure. America seemingly reenacting a $45 billion mistake from the 1980s. GM thought robots would rescue it from Japanese competition.

GM 'FACTORY OF FUTURE' WILL RUN WITH ROBOTS (Published 1984)

AI is playing the same role today. Roger Smith automated entire factories before he understood how they worked. The robots welded doors shut, painted each other, and created more indirect labor than they eliminated.

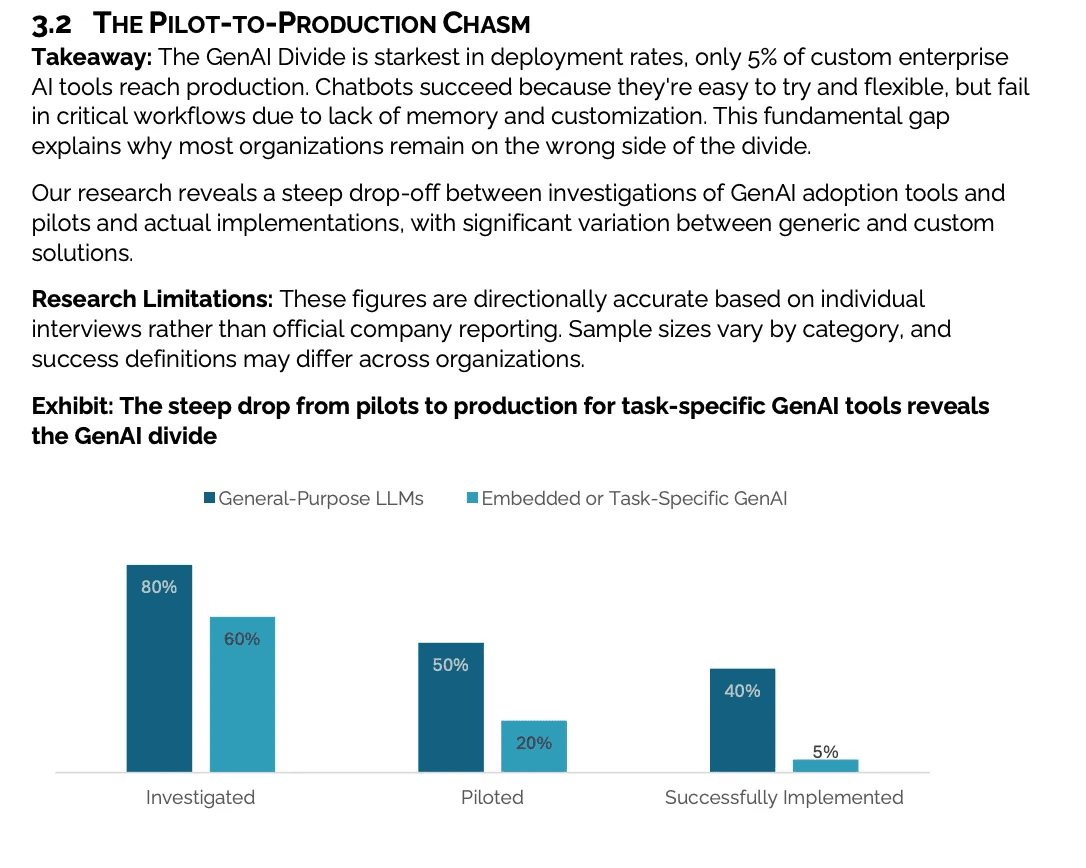

And MIT now reports that 95% of enterprise AI pilots produce zero financial return. That's not a model problem; it's a systems design problem.

https://mlq.ai/media/quarterly_decks/v0.1_State_of_AI_in_Business_2025_Report.pdf

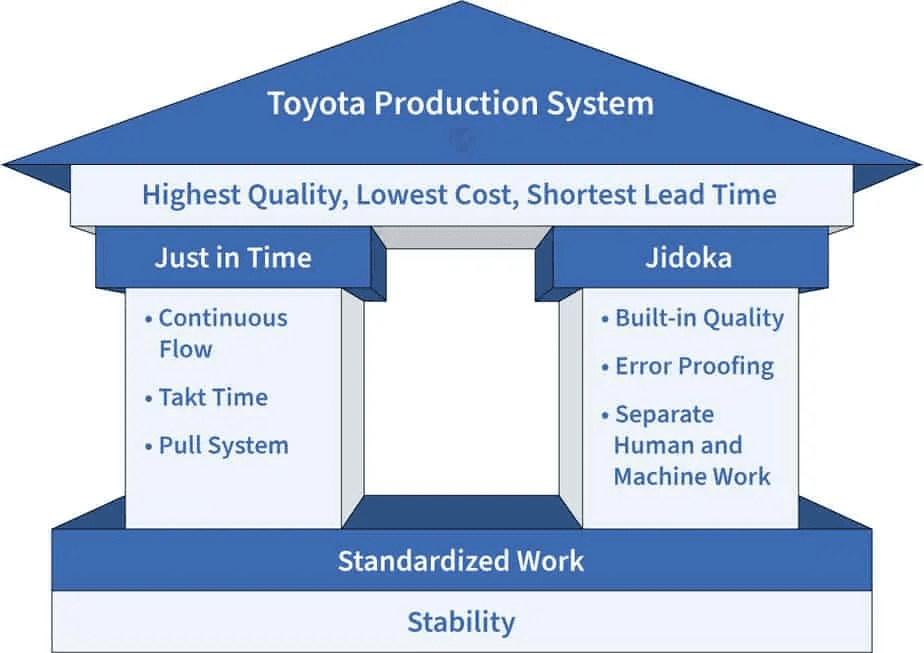

Toyota's system was the opposite. They built Jidoka, or Autonomation, which is automation that refuses to automate anything you haven't mastered manually. Shigeo Shingo said that there are 23 steps between human work and true automation. GM skipped all 23.

https://kanbanzone.com/resources/lean/toyota-production-system/jidoka/

Most companies deploying AI also skipped them. Today, we see LLMs get deployed into workflows that still run on tribal knowledge, undocumented approvals, and spreadsheet archaeology. Meaning, more often than not, the processes are opaque and the models are failing. And knowledge work has no tack time, no andon cord, no standard work sequence.

Most of the real job happens in hallway conversations, Slack threads, and undocumented exceptions. Which is what MIT calls the learning gap. Workers do not know how to translate their tacit work into machine-readable steps. Managers think the model needs to be fine-tuned when the workflow needs an autopsy. Even worse is when AI is deployed in revenue-adjacent areas like marketing instead of cost centers, where Toyota would start, leading to many cosmetic changes rather than structural ones. So the societal risk is not that AI replaces workers, though that is important. It is also the risk that companies never redesign the work. Then AI amplifies the dysfunction with GPU budgets attached. So the GM lesson is simple. Do not automate the wrong work. Fix the work in question until it is boring, predictable, and almost insulting in simplicity. Then let machines handle it. Start with Jidoka logic: Detect, stop, fix, remove root cause, insert mistake-proofing.

In software, this means instrument the workflow before you automate the workflow. Because if you train the model on sloppy processes, the model becomes a high-speed replicator of said sloppy processes. That was GM's entire decade in one sentence.

Toyota proved that small local experiments outperform massive capex bets. GM spent billions while Toyota pulled every cord every time something looked off. Guess who won?

Latest blog